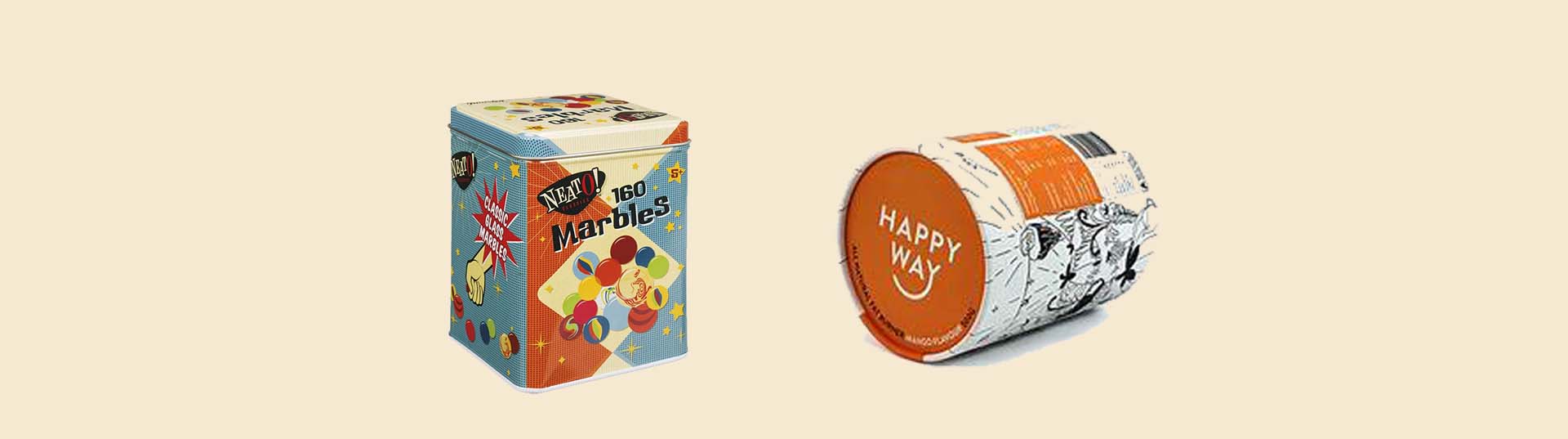

Gift packaging is an era of showing individuality, and every gift is dedicated. How can the gift packaging be free? Prepare a variety of exquisite materials, simple tools, and spend some of your thoughts, and a gift with a unique packaging will suddenly appear in front of everyone.

Every package in this brochure is a variety of style and practicality, gorgeous and realistic, so that every gift of yours will become the focus of everyone attention.

Metal has long been viewed as a packaging format with exceptional sustainability credentials.The raw material used to make metal containers – aluminum or steel – are produced from some of the most abundant elements on earth, and for years metal has enjoyed the most robust global recycling infrastructure of any packaging material because it is infinitely and 100 percent recyclable.The following video by the Metal Packaging Manufacturers Association in the UK gives a brief description of how metal recycles forever.As a global leader in our industry, we have led the way in reducing the amount of metal used in consumer packaging. In addition, we have introduced new manufacturing practices that improve productivity and safety and reduce energy. These efforts make our products more sustainable and, in turn, help our customers meet their own sustainability targets.

Workplace safety is built into every process, procedure and system of the company and the attitudes and values of every employee.A formal Environmental program serves as the backbone to achieve a "Total Safety Culture." With this commitment to sustainability, we know we are on the right track. Here are just a few examples of our recent achievements:In our 2013 Sustainability Report, we recast the data from 2007 through 2012 to normalize usage and emissions per billion units produced. This change was made to present data that offered greater insight by adjusting for year-to-year changes in product mix. We used this same approach to calculate data for 2013 and 2014, the reporting period covered by this report.Since we manufacture a variety of containers in different sizes, using different metals and serving different markets, along with ends, vacuum closures and crowns, we developed a set of conversion factors to transform these container and closure production volumes into 12oz. (Ø211) aluminum beverage can equivalent volumes This modification more accurately represents our efforts to conserve raw material use and reduce emissions over time.

The three conversion factors are explained in more detail below.Type of metal: This factor relates to the specific gravity of the material used in the container, with 1.0 for aluminum and 2.9 for steel. Product functional requirements: This factor adjusts for the fact that different market applications (i.e. beverage cans, food cans and aerosol cans) use different amounts of metal for the same sized can due to very different performance requirements such as pressure performance. These values were determined by comparing the amount of metal required for an approximately 355ml container across different applications. For beverage cans, the value is 1.0 for food cans, the value is 1.5; and for aerosol containers the value is 2.0.

In recognition that this normalization methodology is unfamiliar to those outside of Crown, we are working to obtain third-party validation and will report on results of the evaluation separately. The report does not include environmental data from our specialty packaging plants and our CMB Engineering equipment and tooling division since there is too much variability from year-to-year in their product portfolios to allow the effective normalization of data and together they represent less than 5% of overall revenue. However, the employment demographics, safety performance and other elements of the social category of sustainability are included. This is consistent with how we reported data in the 2013 Sustainability Report, so there are no significant changes from previous reporting periods to highlight or explain.Assets gained from the acquisition of Mivisa Envases, SAU in 2014 are also not included in this report since these plants were not operated by Meebox during the entire reporting period and it was not possible to segment their environmental, production or employment data. However, all of the data from the Mivisa plants will be included in future reports.

Dongguan Factory:

E Village Industrial Zone.Shijie Town.Dongguan City

Guangdong Province 523305 China

Leo Z

All Rights Reserved:Meekom Company